Composite production boards made

of different types of pallets are playing critical roles in the furniture and

other household requirements. The

increased interest of modern man in composite production boards is caused as a

result of its attractive properties like excellent vibration resistance, high

mechanical stability, resistance against water, good wear resistance etc.

|

| Concrete Pallets for Blocks |

There are two types of Plastic Pallets for Concrete Blocks that are generally used for

making composite production boards.

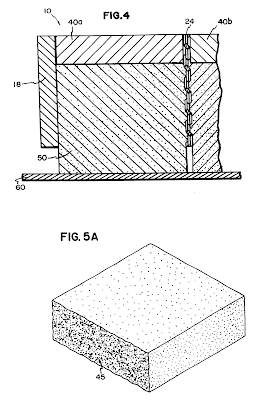

They are generally known as Standard production boards and PRO

production boards. Each side of The PRO

production boards have semi-smooth surfaces on laminated fibre layers. These

semi smooth surfaces give high wear resistance capacity to these boards. In the

case of Standard production boards, resistible shuttering film is used to make

the surfaces wear resistant. The stiffness of the production boards is

increased and deflections of the boards are avoided as a result of fusion of

these composite pallets for production boards.

To avoid moisture absorption and the consequent delimitation, the saw

cut sides of the Block Machine Plastic Pallets are coated.

|

| Block Machine Pallets |

Composite pallets are made up of Hardwood fibres taken from Asian

Plantation. Plantations along the South-East Asia are the location from where

Asian Hardwood fibre is obtained. These composite pallets are made waterproof

by treating it with a suitable waterproof resin. The composite pallets are made

by pressing accompanied by heating processes which are carried out in fully

automated and well calibrated machines. The ratio at which the Hardwood Fibre and Industrial Grade Resin are mixed is decided after extensive research and

experimentation. The Block Machine Plastic Pallets so produced are correctly

machined according to the customer requirements in a more attractive manner with

the help of specially designed machines so that the composite pallets look more

attractive and technologically advanced.

No comments:

Post a Comment