Concrete blocks are known as cement bricks and mainly comes in the use of construction of the building. Automatic and semi-automatic machine are used to construct the concrete blocks. The concrete blocks can be manufactured in small space like in your home also. The most suitable place to construct the Pallets for Concrete Blocks is the wide and open space. It will be better to choose the places which are open, but shaded. This will protect your machinery from the rain. Talking about space then it must have enough area to mix the concrete. After selecting the space, then next step that you need to take is the making of mold. To construct mold, you require planks and nails. Both the material is used to open side box with the inner cavity.

|

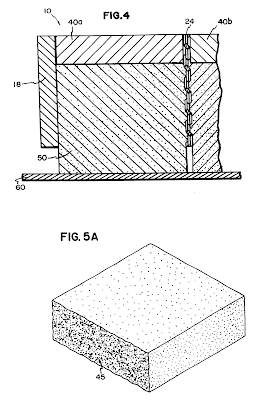

| Pallets for Concrete Blocks |

The Pallets for Block Machine has many variations in size. They range from manual to fully automatic machine. The semi-automatic machine can work for hundred blocks or brick in a year while fully machine are able to produce thousands of blocks and bricks in the day. The working process is same in the entire machine. The machine of concrete blocks has the frame work of steel and this framework holds the other components. To pour wet cement, a hopper is used, which has a frame to hold metal concrete blocks.

|

| Pallets for Block Machine |

To prepare the mixture of Pallets for Concrete Products you need, the large container as large as you can arrange. Then need to collect sand, gravel, and cement. These are essential materials that are required in the construction of the concrete block. When the material gets collect then they are mixed in the proper ratio to form the perfect pallet of concrete blocks. They are mixed in the ratio of 1:2:3. All the ingredients with water are taken in the respected ratio in a container, then they are mixed with the rod.